Evolution of Robotics in Manufacturing

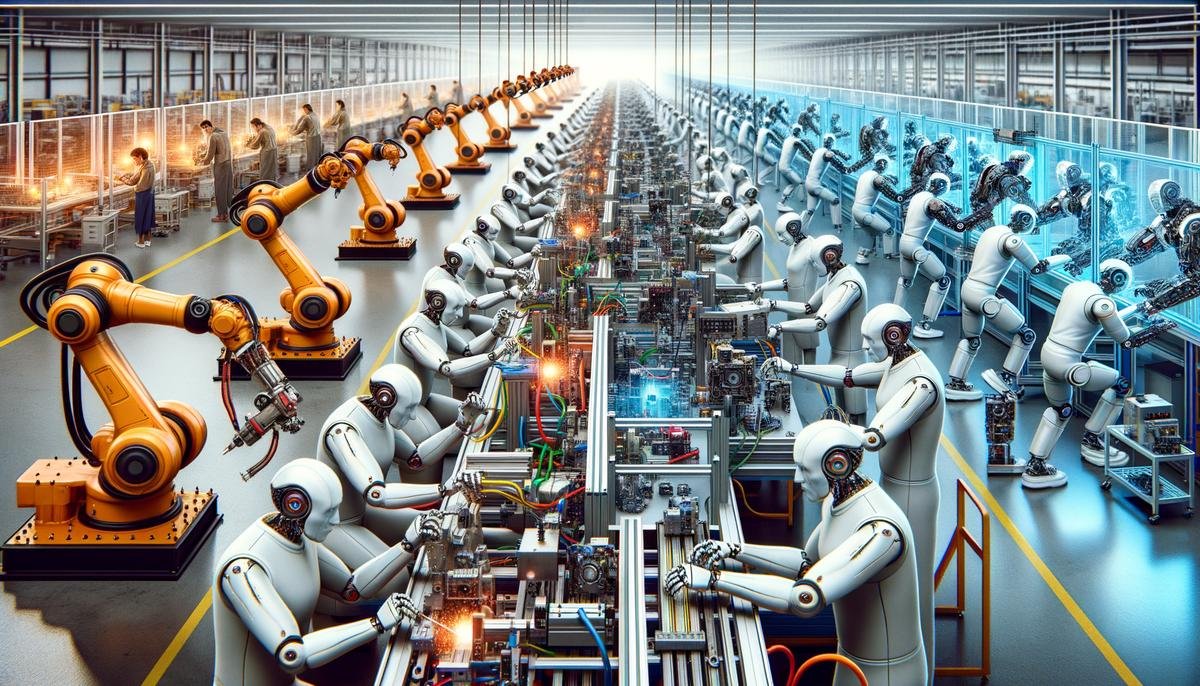

The progression of robotics in manufacturing commenced with basic machines executing repetitive tasks on assembly lines. Early industrial robots focused on simple functions like welding, painting, and assembly. They excelled at consistency and efficiency but lacked flexibility. These robots replaced manual labor for monotonous tasks, boosting productivity and reducing human error.

The landscape has now shifted dramatically with the integration of AI. Modern manufacturing robots do more than just repetitive tasks. They analyze data, learn from their environments, and make independent decisions. This shift to AI-enhanced operations allows for more adaptive and intelligent manufacturing processes.

AI algorithms process vast amounts of data in real-time, optimizing workflows and improving quality control. These systems predict equipment failures, manage inventory efficiently, and adjust to changes in production lines with minimal human intervention. AI ensures products meet high-quality standards while reducing waste and downtime.

Robotic arms, equipped with AI, handle intricate components with precision. Assembly lines now feature collaborative robots, or cobots, working alongside human operators. These cobots enhance productivity by taking on tasks that require both delicate manipulation and repetitive accuracy, creating a safer and more efficient work environment.

AI Technologies Enhancing Robotics

Machine learning (ML), deep learning (DL), and reinforcement learning (RL) are pivotal AI technologies driving advancements in robotics. Each offers unique contributions, enabling robots to perform increasingly intricate and adaptable tasks.

Machine learning has become the foundation for developing intelligent robotics. At its core, ML allows robots to learn from data, identifying patterns and making informed decisions. In manufacturing, ML algorithms analyze vast datasets, helping optimize production processes, predict equipment failures, and ensure high-quality standards.

Deep learning utilizes neural networks to mimic human cognition, enhancing computer vision systems and enabling tasks like gesture and speech recognition. This facilitates more natural human-robot interactions and precision in applications like quality control.

Reinforcement learning is crucial for tasks requiring autonomous decision-making and adaptability. RL algorithms enable robots to learn optimal behaviors through trial and error, refining strategies based on real-time feedback. This capability is vital for applications like autonomous mobility, where robots must navigate dynamic environments.

The integration of ML, DL, and RL enables collaborative robots to work safely alongside humans, learning from their movements and adjusting behavior accordingly. These technologies also contribute to significant cost savings by reducing waste, minimizing downtime, and extending equipment lifespan through predictive maintenance.

Real-World Applications of AI-Integrated Robotics

AI-integrated robotics impact various industries, demonstrating the fusion of mechanical precision and cognitive intelligence in healthcare, manufacturing, logistics, and service sectors.

In healthcare, surgical robots utilize deep learning to analyze medical imagery, providing surgeons with actionable insights for precise procedures. AI-driven robots also revolutionize patient monitoring, tracking vital signs and predicting potential issues.

In manufacturing, AI-powered robots optimize production lines, leverage computer vision for quality control, and employ reinforcement learning for logistics operations. Automotive and electronics manufacturing benefit from robots handling intricate tasks with enhanced precision and efficiency.

The logistics sector utilizes autonomous mobile robots with AI algorithms to optimize picking, packing, and sorting, streamlining order fulfillment. Reinforcement learning enables these robots to navigate warehouse environments independently.

The service sector employs intelligent service robots with conversational AI and analytics, enhancing guest experiences in hospitality and assisting customers in retail settings.

Despite their complexity, AI-powered robots are designed for intuitive use and easy integration, ensuring accessibility for businesses of all sizes, driving broader adoption and innovation across industries.

Educational Pathways in Robotics and AI

Educational pathways in robotics and AI offer structured routes for aspiring professionals. Foundational subjects include mathematics, computer science, and engineering, providing a solid grounding in essential concepts.

- Bachelor’s degrees in fields like Robotics Engineering, Computer Science, or Mechanical Engineering cover key topics such as machine learning, computer vision, control systems, and robotic kinematics. Many universities offer specialized tracks or elective courses focusing on AI and robotics.

- For advanced studies, master’s programs in Robotics or Artificial Intelligence explore sophisticated concepts and applications in depth, involving coursework and research opportunities.

- Professional certifications, like those offered by Stanford University and IBM, provide comprehensive introductions to AI principles and technologies, focusing on practical applications.

Continuous learning through online courses, workshops, and industry conferences is crucial for staying current with the latest advancements and trends.

For those interested in research, Ph.D. programs in relevant fields like Computer Science or Robotics emphasize innovation and theoretical advancements, fostering skills needed to tackle challenging problems in AI and robotics.

Vocational training and hands-on experience through programs like those provided by RoboticsCareer.org offer targeted, industry-endorsed training, ranging from foundational principles to advanced AI integration.

The educational landscape in robotics and AI is diverse, accommodating different expertise levels and career stages, enabling aspiring professionals to build adaptive skill sets in this dynamic field.

Career Opportunities in AI-Powered Robotics

As AI-powered robotics advances rapidly, the career landscape in this field has expanded, offering numerous prospects for skilled professionals. Integrating AI in robotics has given rise to specialized roles catering to the development, deployment, and maintenance of these systems. Here, we explore several key career paths within AI-powered robotics.

Robotic Integrators design, install, and maintain robotic systems, ensuring seamless integration into existing processes and workflows. These professionals need a background in mechanical and electrical engineering, along with expertise in programming languages like Python, C++, and ROS (Robot Operating System). Comprehending AI algorithms, machine learning, and computer vision is crucial.

Robotic Specialists delve into specific aspects of robotics, such as AI programming, computer vision, or machine learning. Their work often involves developing algorithms and software that control robotic behaviors and enhance cognitive capabilities. Robotic specialists should possess in-depth knowledge of AI models, including neural networks and reinforcement learning techniques, as well as proficiency in high-level programming languages and AI frameworks.

Robotics Technicians are vital for the day-to-day operation and maintenance of robotic systems. This role requires a solid grasp of both hardware and software components, including experience with PLC (Programmable Logic Controllers), sensor technology, and basic programming skills.

Project Managers oversee planning, execution, and delivery of robotics projects. They coordinate between teams, manage timelines, budgets, and ensure objectives are met. Successful project managers must thoroughly understand AI and robotics to effectively communicate with technical teams and stakeholders.

Quality Assurance (QA) professionals conduct tests, identify defects, and collaborate with engineers to ensure robotic systems perform reliably and meet specified standards. This role demands a rigorous approach, knowledge of testing methodologies, and familiarity with automation tools and frameworks.

The field has also brought about the need for specialized roles in AI ethics and governance, ensuring robotic systems adhere to ethical standards and regulatory compliance.

As the field grows, new roles continuously emerge, such as Data Scientists in robotics, who analyze vast data generated by robotic systems to derive actionable insights for improving performance and efficiency.

Challenges and Future Developments in AI Robotics

Processing power limitations, algorithm complexity, and the need for extensive and diverse data sets present significant challenges in advancing AI in robotics. However, the future holds promising trends and developments.

One area of focus is developing advanced AI processors specifically designed to handle AI applications’ demands, such as Graphics Processing Units (GPUs) and Tensor Processing Units (TPUs), which can manage complex calculations more efficiently than traditional Central Processing Units (CPUs).

Improved algorithm efficiency is another priority, with researchers working on developing more powerful and computationally efficient AI algorithms through techniques like model pruning, quantization, and lightweight neural architectures.

Increased autonomy and collaboration are key future trends. As AI algorithms become more capable, robots will gain higher autonomy levels, allowing them to perform increasingly complex tasks without human intervention. Collaborative robots (cobots) designed to work alongside humans will benefit from AI advancements that enhance their ability to understand and respond to human actions and emotions.

Integrating AI with emerging technologies like Augmented Reality (AR) and the Internet of Things (IoT) will further expand robots’ capabilities and applications, providing real-time data overlays, guidance, and seamless communication between robotic systems and other devices.

As robots become more integrated into society, addressing ethical implications and governance of AI and robotics systems will be paramount. Ensuring AI implementations are transparent, fair, and accountable is crucial for building public trust and ensuring responsible deployment of robotic technologies.

Integrating AI in robotics reshapes industries by enhancing efficiency, precision, and adaptability. As advancements continue, AI-powered robots will play an increasingly vital role in various sectors, driving innovation and operational excellence.