AI-Driven Inventory Management

Accurate Demand Forecasting

AI processes data from various sources to predict inventory needs, matching stock levels to demand. This reduces the risk of stockouts or excess inventory.

Real-Time Inventory Tracking

AI-driven tools monitor stock levels continuously, providing instant updates on fast-selling items or slow-moving stock.

Automated Replenishment

The system automatically triggers purchase orders when inventory drops below set levels, ensuring shelves remain stocked without manual intervention.

Reducing Overstocking and Stock-Outs

AI balances inventory levels, minimizing both overstocking and stockouts. This optimizes warehouse space and resources while maintaining customer satisfaction.

Optimizing Logistics with AI

Improved Route Planning

AI analyzes real-time data to suggest the most efficient routes, considering factors like traffic and weather conditions.

Reducing Fuel Consumption

By optimizing delivery routes, AI helps reduce fuel usage, cutting costs and improving efficiency.

Ensuring Timely Deliveries

AI factors in potential delays to maintain punctual deliveries, improving overall logistics performance.

Real-Time Traffic Updates and Re-Routing

The system provides dynamic re-routing based on current traffic conditions, helping drivers avoid delays.

Predictive Maintenance

AI monitors vehicle health, predicting potential issues before they cause breakdowns, ensuring smoother operations.

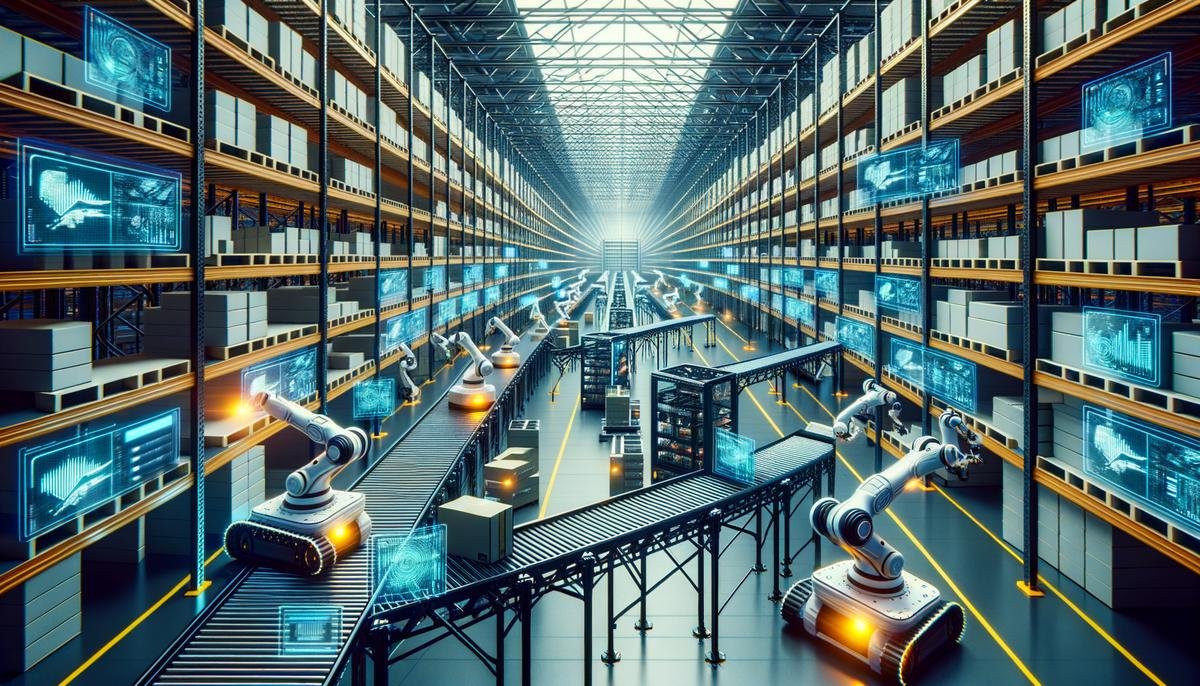

AI in Warehouse Management

Automating Routine Tasks

AI-powered robots handle sorting, packing, and transporting items, freeing up workers for more strategic roles.

Optimal Item Placement

AI determines efficient item placement within the warehouse, reducing picking times and improving overall efficiency.

Improved Safety Measures

AI-powered sensors and cameras monitor for potential hazards, alerting staff to safety issues in real-time.

Real-Time Data Analysis

AI processes warehouse data to provide actionable insights on operations, helping managers make informed decisions.

Dynamic Adjustments

AI systems can reconfigure workflows in real-time to handle changes in demand or inventory levels, maintaining operational efficiency.

AI for Supplier and Vendor Management

AI-Driven Supplier Selection

AI evaluates potential suppliers based on criteria like cost efficiency, quality, and reliability, streamlining the selection process.

Performance Tracking

Real-time monitoring of supplier performance helps maintain high standards and identifies issues promptly.

Predictive Analytics for Supplier Lead Times

AI forecasts lead times accurately, allowing for better planning and scheduling.

Optimizing Supplier Logistics

AI provides real-time tracking and routing solutions to improve efficiency in supplier logistics.

Enhanced Supplier Relationships

AI tools help map interaction histories and identify trends, supporting stronger supplier partnerships.

Risk Mitigation

AI systems scan for potential supply chain disruptions, allowing for proactive risk management.

Challenges and Future of AI in Supply Chain

Challenges

- System complexity and resource requirements

- High initial costs for hardware and integration

- Training costs and potential resistance to change

- Scalability issues

Future Prospects

- Advanced predictive analytics for demand forecasting

- Improved supply chain resilience and adaptability

- Enhanced transparency through integration with blockchain and IoT

- Increased automation and efficiency in complex operations

- Support for sustainability goals through optimized resource use

AI is transforming supply chains into proactive, agile networks. The future promises sophistication, resilience, and efficiency, setting a new standard for operational excellence.

- McKinsey. AI-enabled supply-chain management: applications and benefits. McKinsey & Company. 2021.

- Gartner. Gartner Survey Reveals 88% of Supply Chain Organizations Have Invested in AI. Gartner. 2022.

- IDC. Worldwide Spending on Artificial Intelligence Systems Will Grow to Nearly $35.8 Billion in 2019, According to New IDC Spending Guide. IDC. 2019.