Understanding Llamasoft’s AI Solutions

Llamasoft’s AI tools offer advanced features for supply chain management. These include predictive analytics, demand forecasting, and supply chain modeling. By analyzing vast amounts of data from various sources, these tools help businesses anticipate potential disruptions and make informed decisions.

Key features of Llamasoft’s AI solutions include:

- Inventory optimization: Algorithms determine ideal stock levels, reducing excess inventory and preventing stockouts.

- Supplier management: The AI evaluates supplier performance, monitoring delivery times, order accuracy, and product quality.

- Transportation management: By analyzing data from GPS, traffic conditions, and weather forecasts, Llamasoft optimizes shipping routes and schedules.

- Risk management: Predictive capabilities help anticipate and mitigate risks, suggesting alternative suppliers or routes when necessary.

- Real-time visibility: The platform provides a comprehensive view of the entire supply chain, from raw materials to finished products.

Integrating Llamasoft’s AI tools with existing supply chain systems is straightforward, creating a cohesive ecosystem that improves communication and reduces inefficiencies across the supply chain.

Optimizing Inventory Management

Llamasoft’s AI tools excel at managing inventory through:

- Predictive demand forecasting: By analyzing historical sales data, market trends, and macroeconomic indicators, the algorithms accurately predict customer needs.

- Real-time inventory tracking: The system provides continuous visibility of stock levels across the supply chain.

- Proactive management: The AI detects patterns and anomalies, adjusting reordering schedules to avoid gaps or excess stock.

- Scenario simulation: Users can run ‘what-if’ scenarios to understand the impact of different inventory strategies without real-world consequences.

- Overstock and stockout reduction: The tools identify underutilized items and suggest steps to minimize holding costs while anticipating demand spikes to prevent stockouts.

By integrating these strategies, Llamasoft’s AI transforms inventory management from a reactive practice to a dynamic, forward-thinking approach.

Enhancing Supplier and Risk Management

Llamasoft’s AI tools improve supplier and risk management by:

- Performance monitoring: The system tracks delivery times, order accuracy, and quality metrics to identify trends and potential issues.

- Early warning system: AI flags performance deviations, allowing for quick intervention before problems escalate.

- Supplier diversification: The tools suggest potential new suppliers, assessing their reliability, costs, and alignment with business needs.

- Risk prediction and mitigation: By evaluating various data points, the AI forecasts potential risks and prepares alternative strategies.

- Real-time data integration: The system continuously processes new information, updates risk profiles, and suggests mitigation strategies.

- Improved supplier negotiations: Data-driven insights provide concrete evidence for more effective contract negotiations.

These features help businesses build a resilient and efficient supply chain that can adapt to changing demands and potential disruptions.

Streamlining Transportation and Logistics

Llamasoft’s AI tools optimize transportation and logistics through:

- Route optimization: The system analyzes data from GPS, traffic conditions, and weather forecasts to determine the most efficient routes.

- Real-time adjustments: AI recalculates routes in response to unexpected events, maintaining smooth operations.

- Load optimization: By considering factors such as delivery destination, cargo type, and weight distribution, the AI maximizes efficiency and reduces trips.

- Real-time tracking: The tools provide visibility into every step of the logistics process, allowing for informed decision-making.

- Inbound logistics coordination: Predictive analytics help prepare for incoming shipments, avoiding congestion at receiving docks.

- International shipping optimization: The AI calculates the best combination of routes for cross-border shipments, considering factors like port congestion and regulatory changes.

These features lead to faster deliveries, reduced shipping costs, and improved customer satisfaction. By shifting from a reactive to a proactive approach, businesses can anticipate and address potential issues before they impact operations.

“AI-driven logistics optimization can reduce transportation costs by up to 15% and improve on-time deliveries by 20%.”1

Real-World Case Studies

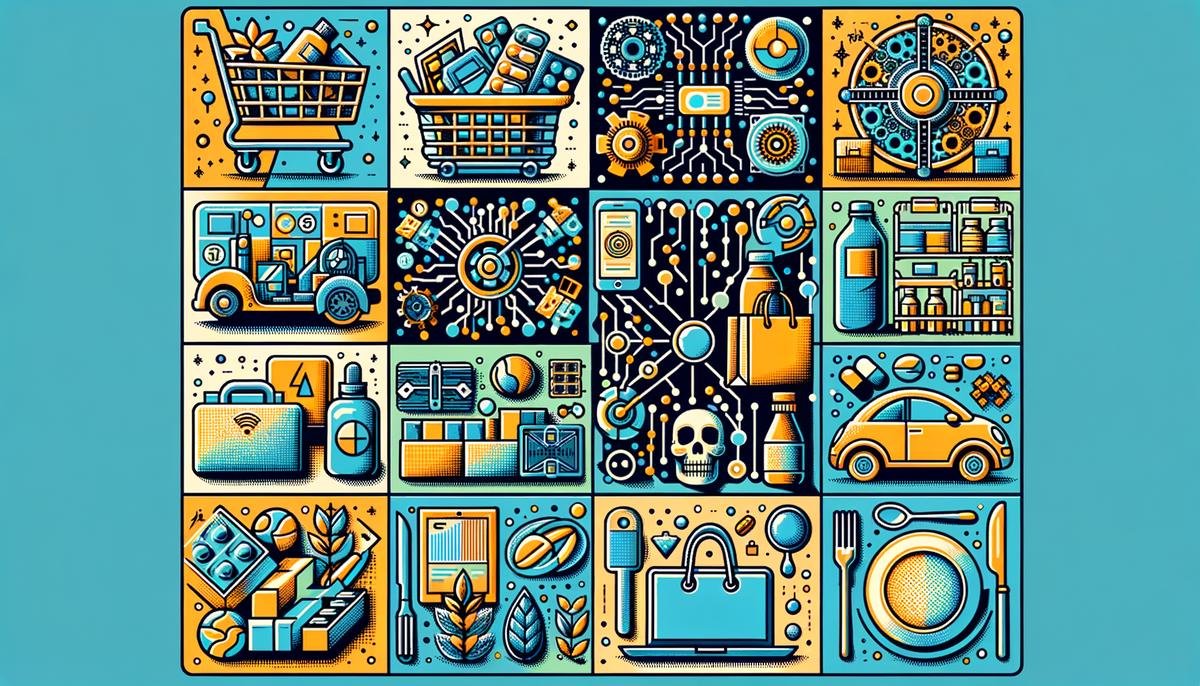

Here are examples of how companies have benefited from Llamasoft’s AI solutions in supply chain management:

- Consumer Goods Giant: Faced demand fluctuations and inconsistent supplier performance. Implementing AI-powered demand forecasting and supplier management tools reduced stockouts by 15% and rush order costs by 10%.

- Global Electronics Manufacturer: Struggled with high transportation costs and inefficient routing. AI optimization tools leveraged real-time data to streamline logistics, resulting in a 25% reduction in transportation costs and improved delivery times.

- Automotive Parts Supplier: Battled inventory imbalances. After integrating AI inventory optimization tools, achieved a 20% reduction in carrying costs and a 30% decrease in production halts.

- Pharmaceutical Company: Needed better supply chain traceability for regulatory compliance. AI solutions automated documentation verification, enhancing credibility with regulators and customers.

- Retail Giant: Used AI-powered resilience tools to manage volatile holiday season demand. By anticipating bottlenecks and adjusting inventory levels, increased holiday season sales by 35%.

- Food and Beverage Company: Dealing with perishables, implemented AI tools for optimal ordering and supplier management. Resulted in a 40% reduction in spoilage and minimized supplier-related disruptions.

These case studies demonstrate how Llamasoft’s AI solutions have helped companies across industries improve efficiency, reduce costs, and enhance customer satisfaction.

Integrating Llamasoft’s AI solutions into your supply chain operations offers a strategic advantage, transforming challenges into streamlined processes and enhancing overall efficiency. By using advanced tools for inventory management, supplier relations, risk mitigation, and logistics, you can create a resilient and responsive supply chain that meets the demands of modern business.

“AI-driven supply chain management is not just a competitive advantage; it’s becoming a necessity in today’s fast-paced, global marketplace.”1

Consider the following benefits of AI integration:

- Enhanced Forecasting: AI algorithms can analyze vast amounts of data to predict demand patterns with unprecedented accuracy.

- Real-time Optimization: Continuous adjustment of inventory levels and logistics routes based on live data inputs.

- Risk Mitigation: Early detection and response to potential disruptions in the supply chain.

- Cost Reduction: Improved efficiency leads to significant savings in transportation, inventory, and operational costs.

As supply chains become increasingly complex, the role of AI in managing these intricacies becomes more crucial. Companies that embrace these technologies position themselves at the forefront of innovation and operational excellence.