Artificial General Intelligence (AGI) aims to understand and solve a wide range of problems, much like a human brain. This could lead to fully automated factories and smarter production lines in manufacturing.

Understanding AGI and Its Potential in Manufacturing

Artificial General Intelligence (AGI) represents a leap beyond narrow AI. While narrow AI excels at specific tasks, AGI aims to understand, learn, and solve a wide range of problems. This versatility could enable fully automated factories where machines aren’t limited to repetitive tasks.

AGI could take manufacturing further than current AI systems. For example, it could proactively adapt to emerging patterns in machine behavior, shifting from reactive to proactive maintenance to reduce downtime.

In smart factories, AGI could oversee entire production lines, adjusting schedules based on real-time changes in demand or supply chain constraints. This flexibility could minimize waste and maximize efficiency.

AGI’s advanced cognitive abilities could also revolutionize supply chain management. It could:

- Predict market trends

- Analyze geopolitical factors

- Evaluate environmental impacts

This would enable supply chains to be more resilient and adaptive to global changes.

In manufacturing research and development, AGI could expedite the innovation cycle by simulating numerous scenarios and analyzing vast datasets. This could help engineers develop new materials and products faster.

AGI could also enhance worker safety by monitoring environments in real-time and anticipating potential hazards. This foresight would create safer working conditions, protecting employees from accidents.

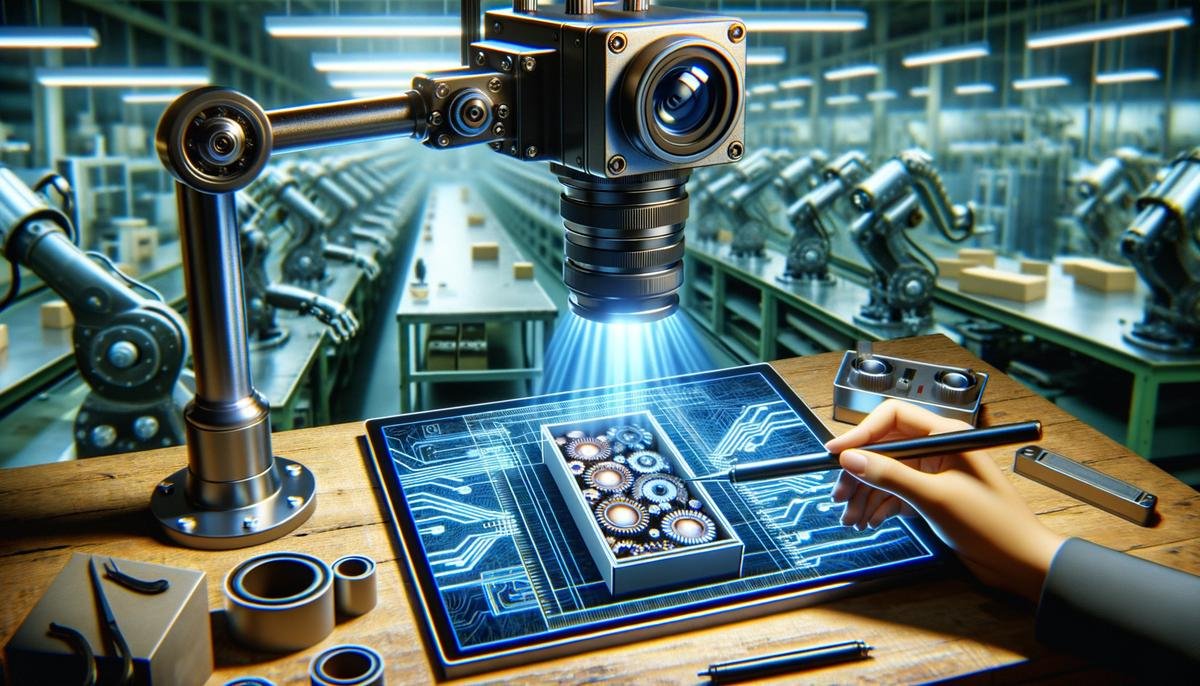

Current State of AI in Manufacturing

AI is already transforming manufacturing in several key areas:

- Predictive maintenance: AI systems analyze data from sensors to foresee equipment failures before they occur. Companies like KONUX use AI algorithms to optimize maintenance plans, extending machine life and minimizing downtime.

- Quality control: AI-powered visual inspections offer enhanced accuracy and speed compared to manual methods. These systems can detect subtle defects in products, ensuring higher quality standards are met consistently.

- Supply chain optimization: AI systems use complex algorithms to forecast demand, optimize inventory, and streamline logistics. Companies like Blue Yonder utilize AI to adjust forecasts and replenish stock dynamically, enhancing supply chain resilience and efficiency.

- Collaborative robots (cobots): These AI-powered robots work alongside human workers, handling repetitive and potentially hazardous tasks. Rethink Robotics develops cobots that can be easily programmed by human co-workers.

- Autonomous factories: Xiaomi’s fully autonomous smart factory in Beijing operates 24/7 without human labor. It uses AI to monitor production, identify issues, and optimize processes via the Xiaomi Hyper Intelligent Manufacturing Platform (IMP).

Other industry leaders like Tesla, Google, and Amazon are also incorporating AI in their operations, from autonomous vehicles to fulfillment centers, resulting in faster processing times and improved efficiency.

Technologies Driving AGI Development

Several technologies are driving AGI development:

- Neural networks and deep learning: These technologies, inspired by the human brain, enable AI systems to tackle complex tasks like image and speech recognition. Deep learning employs multiple layers of nodes to extract hierarchical features from raw data.

- Reinforcement learning: This approach allows machines to learn by interacting with their environment and receiving feedback. It’s essential for creating adaptive systems that can handle novel scenarios.

- Cognitive architectures: These aim to replicate human cognitive processes such as perception, memory, and decision-making. Projects like the Human Brain Project explore neural mechanisms to construct comprehensive models of brain function.

- Computational neuroscience: This field merges neuroscience with computational models to study brain functions and inform the design of more sophisticated neural networks and learning algorithms.

- Machine learning approaches: Techniques like supervised learning, unsupervised learning, and reinforcement learning provide the foundation for machines to learn from data and make predictions.

The combination of these technologies enhances the versatility, adaptability, and cognitive capabilities of AI systems, bringing us closer to realizing AGI.

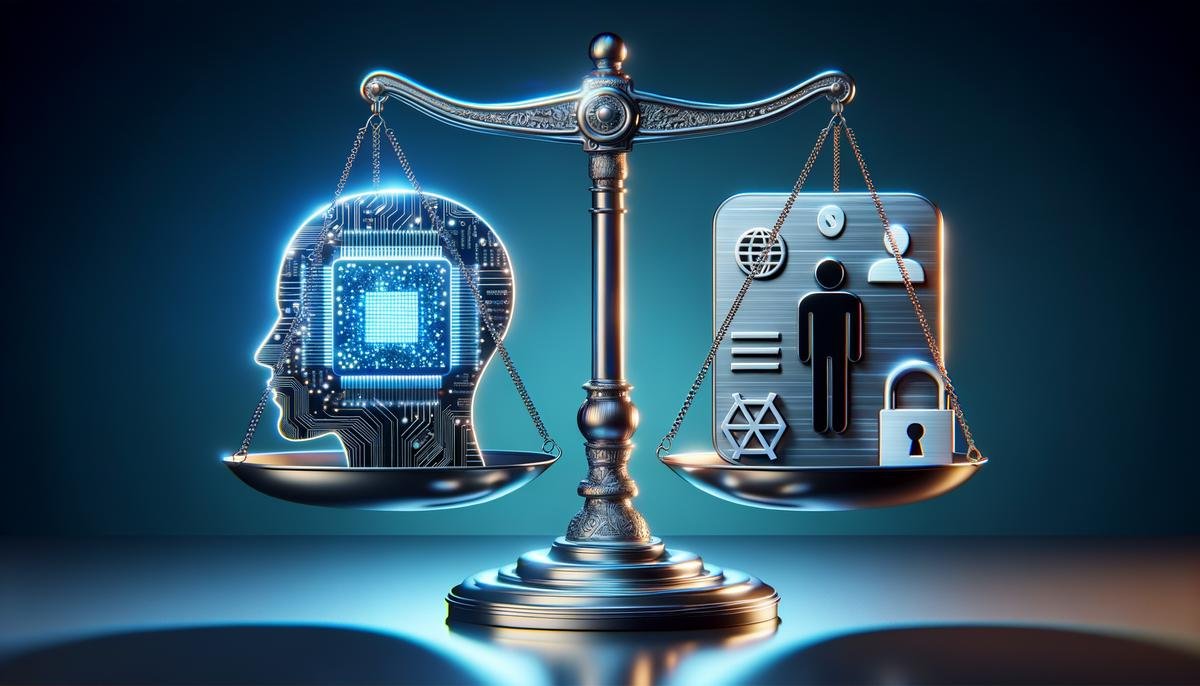

Challenges and Ethical Considerations

AGI development faces significant challenges and ethical considerations:

Technical challenges:

- Emulating human cognition’s complexity

- Scalability and computational resource demands

- Algorithmic limitations in generalizing across diverse tasks

Ethical and safety concerns:

- Bias in AI decision-making

- Privacy risks from extensive data processing

- Ensuring AGI remains under human control

- Aligning AGI systems with human values and ethics

Economic and social impact:

- Potential job displacement

- Risk of concentrated wealth and power

- Need for workforce preparation and social safety nets

Addressing these challenges and ethical concerns is crucial for harnessing AGI’s potential while ensuring fair, safe, and equitable outcomes in manufacturing and beyond.

Future Prospects and Real-World Applications

AGI’s future in manufacturing holds significant potential:

- Fully automated factories: AGI could oversee entire production processes, adapting workflows based on real-time analytics and market demands.

- Advanced robotics: AGI-powered robots could handle complex tasks requiring cognitive skills and decision-making, collaborating seamlessly with human workers.

- Smart supply chains: AGI could predict and mitigate supply chain disruptions, optimizing inventory management and logistics.

- Accelerated R&D: AGI could speed up innovation by analyzing vast datasets and simulating scenarios, potentially shortening development timelines.

- Sustainability improvements: AGI could optimize resource use, reduce waste, and manage energy consumption more efficiently in manufacturing processes.

- Healthcare manufacturing: AGI could manage pharmaceutical or medical device production with extreme precision, adapting quickly to changes in demand.

These advancements could significantly enhance efficiency, productivity, and innovation in manufacturing, potentially redefining industrial capabilities and economic growth.

AGI has the potential to automate complex tasks and decision-making in manufacturing. Its ability to adapt and optimize in real-time could lead to significant improvements in efficiency and innovation across industries.

- Goertzel B, Pennachin C. Artificial General Intelligence. Springer; 2007.

- Müller VC, Bostrom N. Future Progress in Artificial Intelligence: A Survey of Expert Opinion. In: Fundamental Issues of Artificial Intelligence. Springer; 2016:555-572.

- Lee J, Davari H, Singh J, Pandhare V. Industrial Artificial Intelligence for Industry 4.0-based Manufacturing Systems. Manufacturing Letters. 2018;18:20-23.

- Tao F, Qi Q, Liu A, Kusiak A. Data-driven smart manufacturing. Journal of Manufacturing Systems. 2018;48:157-169.